InSky OPGW

Used by electric utilities on transmission lines with the voltage of 35 kV and higher for creating optical communication lines and protecting the power lines from lightning strikes.

InAir ADSS

Applied for aerial installation on distribution and power transmission lines for building long distance optical communication systems.

Specialty Cable

Used for distributed fiber optic sensing in different applications.

InFire Rated

Used for indoor and outdoor applications where fire resistance is a must. Remain functional under direct flame for at least 180 minutes.

InDuct

Applied in ducts, conduits and trays with no risk of rodent attacks. Can also be lashed.

InArmor

Designed for high reliability in harsh environments with potential mechanical impact. Applied in all ground types, swamps, and harsh rivers.

BlownIn

Designed for air blowing in ducts and microducts for building reliable underground communication networks.

InWater

Designed for underwater application with increased crush and tensile loads.

InAir Figure 8

Used for cost-effective one-step aerial installation mostly in rural areas where the spans between poles are not long .

InControl

Applied in substations for control purposes.

InHome FTTH

Used to create communication lines between the common distribution box and a location inside the building (including vertical runs), between entrances or corridors in office buildings.

InDrop FTTH

Applied for aerial installation on transmission towers, lightning poles, between buildings and structures for communication networks in rural areas.

The standard design for ruggedness and reliability. It is also the best solution for long spans. With a tracking-resistant jacket, it can be used in electric fields up to 25 kV.

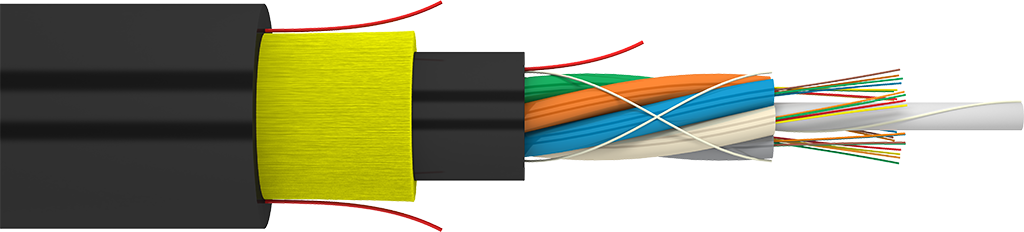

Central strength member (dielectric fiberglass reinforced plastic)

Optical fiber

PBT loose tube filled with water-blocking gel

Water-swellable yarns

Inner jacket

Reinforcing member – aramid yarns

Jacket

Ripcord

InAir ADSS DJ (All-Dielectric Self-Supporting Double Jacket) is the most reliable among all-dielectric self-supporting double jacketed fiber optic cables. It is the best ADSS aerial solution for long spans as it can be installed in intercity communication lines with distances between towers reaching 1,640 ft. Its maximum rated design tension can reach 22,481 lb. With a track-resistant jacket, it can be used in electric fields up to 25 kV. It also has a wide range of operating temperatures from -76°F to +158°F and installation temperatures from -22°F to +158°F.

Check how this aerial fiber optic cable can be deployed in FTTH system.

Visit our Configurator ACES: Advanced Cable Engineering System, a unique software tool to help engineers select the optimal ADSS design along with the associated accessories. ACES ADSS also assists engineers and planners in preparing cost estimates, generating a complete bill of materials, determining reel lengths, and planning logistics. ACES SPOT makes calculation of space potential around overhead transmission lines with ADSS cables as well as choosing the optimal ADSS cable attachment point on the tower very easy. Finally, ACES CATS can be used for simple calculations of tension and sags.

| Maximum rated cable load (MRCL), lb | 899 | ||

| Crush | 126 lb/in (0.22 kN/cm) | ||

| Fiber count, up to | 72 (6х12) | 96 (8х12) | 144 (12х12) |

| Cable diameter, in | 0.488 | 0.567 | 0.705 |

| Cable weight, lb/ft | 0.076 | 0.1 | 0.154 |

| Minimum bending radius, in | 7.3 | 8.5 | 10.6 |

| Maximum rated cable load (MRCL), lb | 1349 | ||

| Crush | 126 lb/in (0.22 kN/cm) | ||

| Fiber count, up to | 72 (6х12) | 96 (8х12) | 144 (12х12) |

| Cable diameter, in | 0.488 | 0.567 | 0.705 |

| Cable weight, lb/ft | 0.077 | 0.101 | 0.155 |

| Minimum bending radius, in | 7.3 | 8.5 | 10.6 |

| Maximum rated cable load (MRCL), lb | 1798 | ||

| Crush | 126 lb/in (0.22 kN/cm) | ||

| Fiber count, up to | 72 (6х12) | 96 (8х12) | 144 (12х12) |

| Cable diameter, in | 0.492 | 0.571 | 0.705 |

| Cable weight, lb/ft | 0.079 | 0.102 | 0.156 |

| Minimum bending radius, in | 7.4 | 8.6 | 10.6 |

| Maximum rated cable load (MRCL), lb | 2248 | ||

| Crush | 126 lb/in (0.22 kN/cm) | ||

| Fiber count, up to | 72 (6х12) | 96 (8х12) | 144 (12х12) |

| Cable diameter, in | 0.496 | 0.575 | 0.709 |

| Cable weight, lb/ft | 0.081 | 0.104 | 0.158 |

| Minimum bending radius, in | 7.4 | 8.6 | 10.6 |

| Maximum rated cable load (MRCL), lb | 2698 | ||

| Crush | 126 lb/in (0.22 kN/cm) | ||

| Fiber count, up to | 72 (6х12) | 96 (8х12) | 144 (12х12) |

| Cable diameter, in | 0.5 | 0.575 | 0.713 |

| Cable weight, lb/ft | 0.083 | 0.106 | 0.16 |

| Minimum bending radius, in | 7.5 | 8.6 | 10.7 |

| Maximum rated cable load (MRCL), lb | 3372 | ||

| Crush | 126 lb/in (0.22 kN/cm) | ||

| Fiber count, up to | 72 (6х12) | 96 (8х12) | 144 (12х12) |

| Cable diameter, in | 0.508 | 0.583 | 0.717 |

| Cable weight, lb/ft | 0.086 | 0.109 | 0.164 |

| Minimum bending radius, in | 7.6 | 8.7 | 10.7 |

| Maximum rated cable load (MRCL), lb | 4496 | ||

| Crush | 126 lb/in (0.22 kN/cm) | ||

| Fiber count, up to | 72 (6х12) | 96 (8х12) | 144 (12х12) |

| Cable diameter, in | 0.528 | 0.602 | 0.732 |

| Cable weight, lb/ft | 0.092 | 0.114 | 0.17 |

| Minimum bending radius, in | 7.9 | 9.1 | 11 |

| Operating temperature | -58°F ... +158°F |

| Installation temperature | -22°F ... +158°F |

| Transportation and storage temperature | -58°F ... +158°F |

| Minimum bending radius | 15 x cable diameter |

| Design life | 25 years |

Your guiding light

in Incab America universe